- HOME

- MATTRESS MACHINE

- FOAM MACHINE

- PILLOW MACHINE

- SOFA MACHINE

- PROJECT SOLUTION

- NEWS

- COMPANY PROFILE

- CONTACT US

|

Parameters |

double-sided mold box |

|

stirring volume |

10 cubic meters |

|

stirring speed |

12rpm |

|

Oil cylinder pressure |

15T |

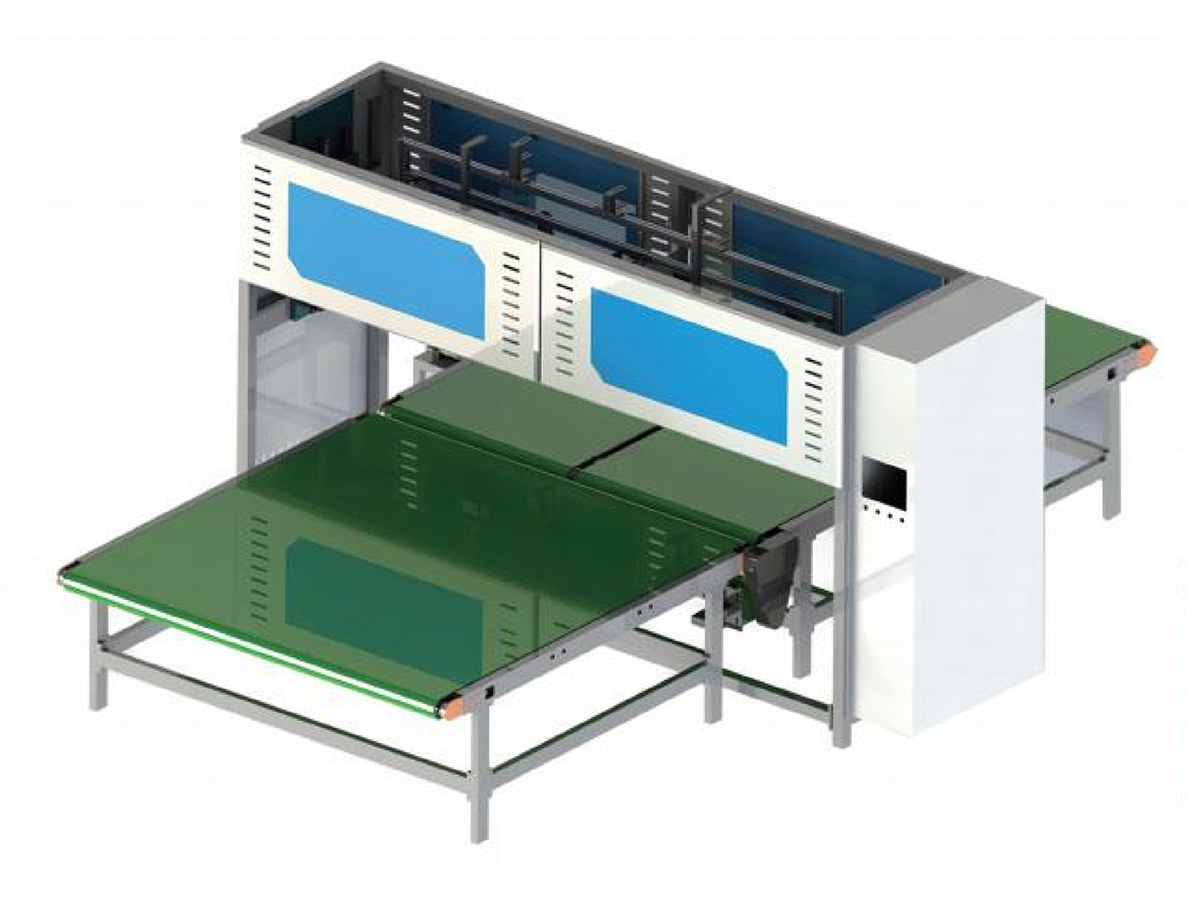

Product Description

The foam regeneration machine includes a set of mixing barrels for mixing foam blocks and

adhesives and a set of hydraulic regeneration molds. The crushed foam is blown into the mixing

barrel, mixed and poured into standard molds, and becomes recycled foam under oil pressure. .

The foam recycling machine is mainly used to mix the crushed foam and glue, and then press it through

the foam molding die and the hydraulic system to form a recycled foam with the corresponding required

density. This machine has a complete set of assembly line for stirring, mixing, and pressure forming, and the

production efficiency is extremely high.

|

Technical Specification |

||||

|

Parameters |

Without steam |

with steam |

double-sided mold box |

double oil cylinder |

|

stirring volume |

10 cubic meters |

10 cubic meters |

10 cubic meters |

10 cubic meters |

|

stirring speed |

12rpm |

12rpm |

12rpm |

12rpm |

|

Oil cylinder pressure |

15T |

15T |

15T |

30T |

|

molding size |

L2*W1.5*H1m |

L2*W1.5*H1m |

L2*W1.5*H1m |

L2*W1.5*H1m |

|

steam device |

100/200L |

100/200L |

100/200L |

100/200L |

|

machine power |

12KW |

12KW |

12KW |

12KW |

|

machine foot space |

L7*W4*H5.5m |

L7*W4*H5.5m |

L7*W4*H5.5m |

L7*W4*H5.5m |

Please make sure your contact information iscorrect. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.