- HOME

- MATTRESS MACHINE

- FOAM MACHINE

- PILLOW MACHINE

- SOFA MACHINE

- PROJECT SOLUTION

- NEWS

- COMPANY PROFILE

- CONTACT US

|

Hexagonal Wood Barrel (ASTM F 1566) |

109kg, length 915±75 mm |

|

Cylinder wood barrel (EN1957) |

140kg, length 1000mm |

|

Maximum size of mattress |

2200m×2000m×400mm |

|

Test speed |

0-20 r/min |

|

Control method |

PLC |

Product Applications

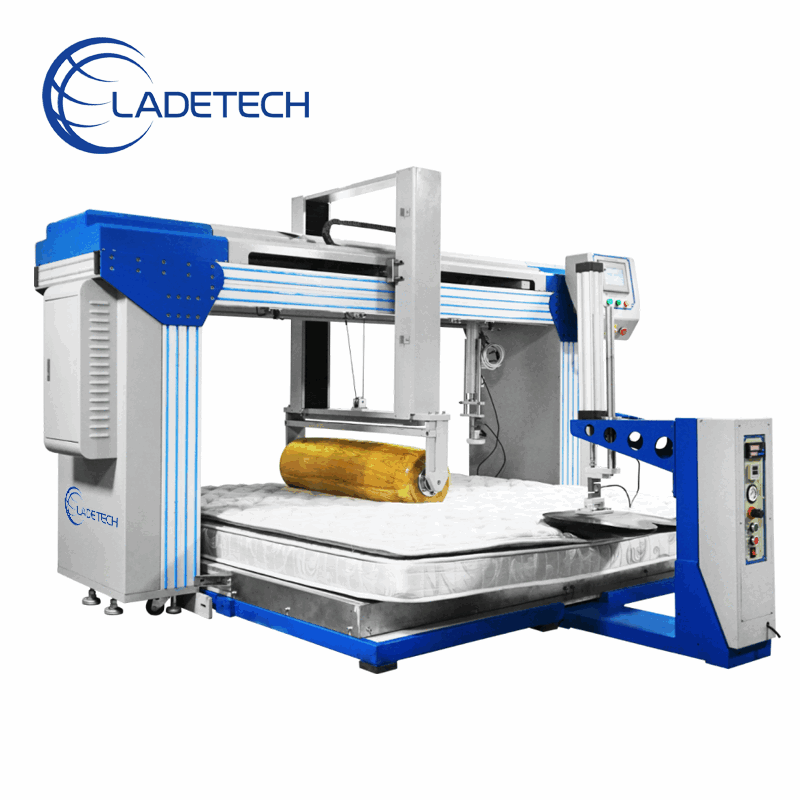

three functions of Integrated Mattress Test Machine

(1) DURABILITY TEST

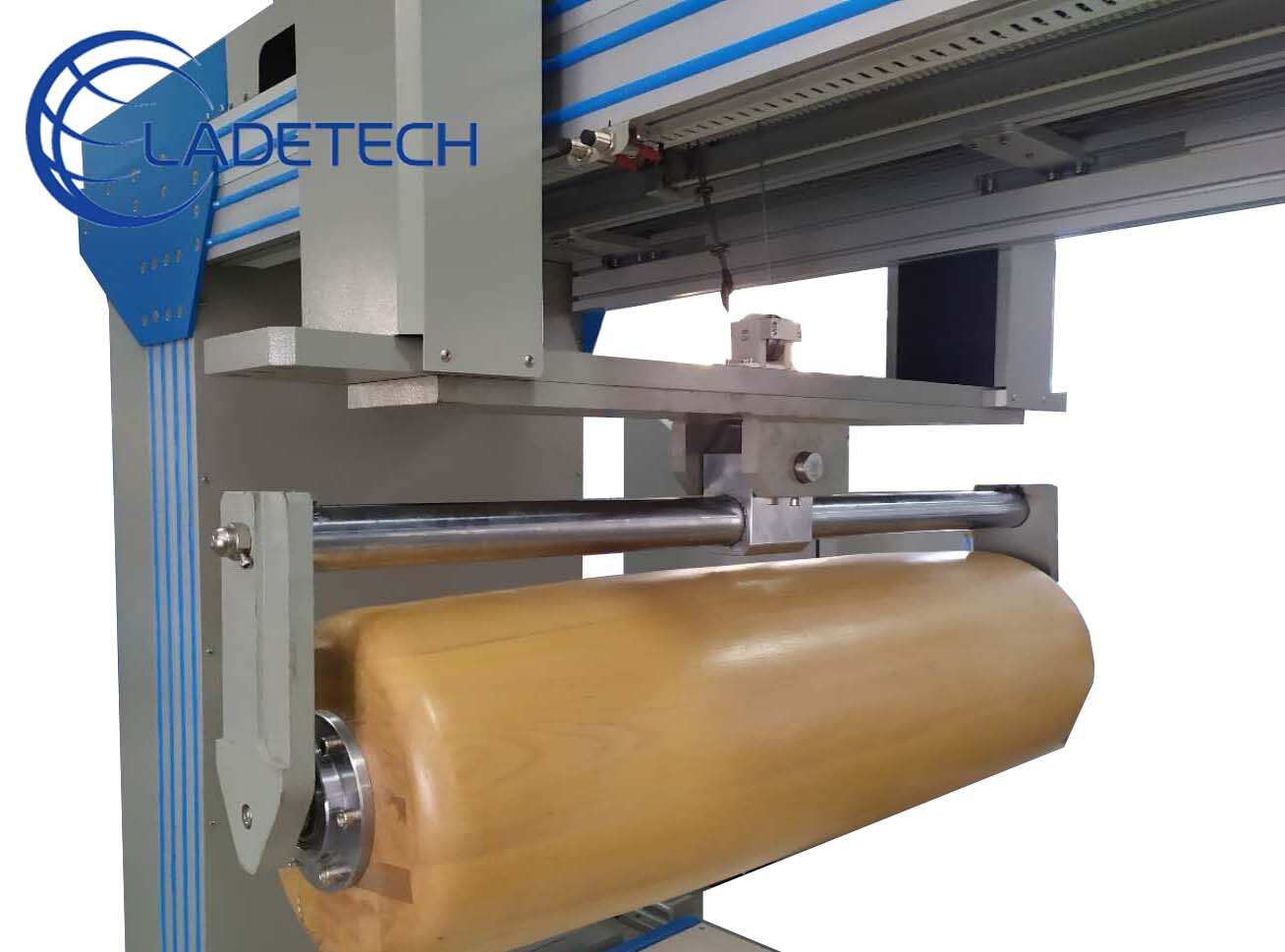

Using a horizontal hexagonal wooden drum roll or cylinder (both ends of the diameter of 250 mm, the middle part of the 300 mm, rolling back and forth on the mattress, simulate human motion to assess the durability of the mattress.

The Mattress Durability Tester has been manufactured to determine the durability of any type of mattress and box spring unit, regardless of the materials of construction, by simulating long-term use conditions. It consists of a weighted roller which moves width ways across a test mattress to simulate body movement. The length of stroke to which the Roller moves is very easily adjusted, by sliding the stroke adjusters to left or right, to suit the relevant mattress under test. Unloading and loading of the Roller onto the test mattress is done easily via a motor driven lifting assembly.

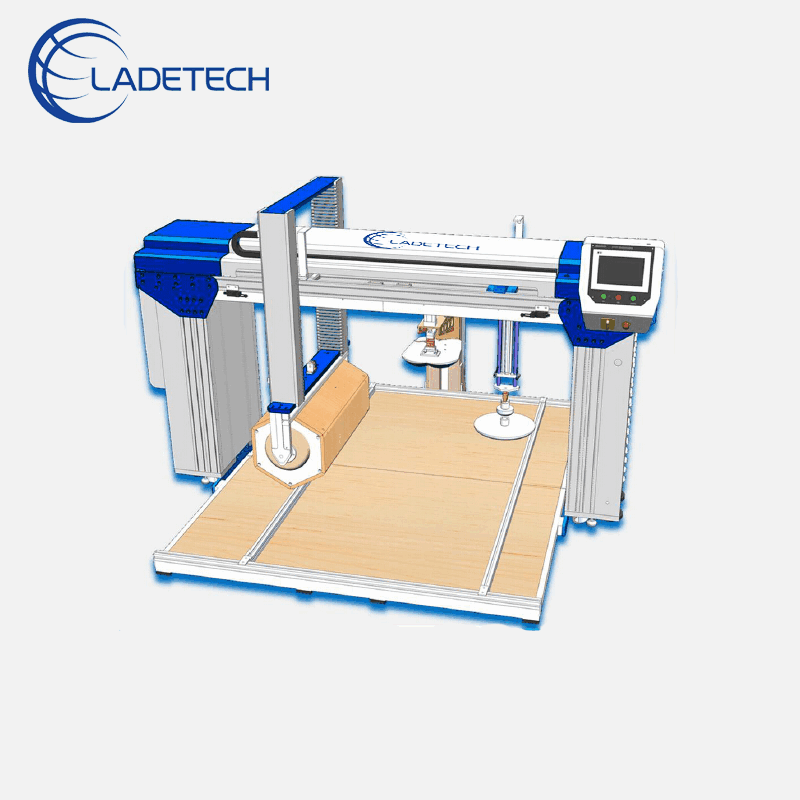

(2) EN HARDNESS & HEIGHT CHANGE TEST

The test machine combines the loading device (roll) with a hardness measuring device. Thus, firmness test can be carried out according to ASTM F 1566 or EN 1957, without the need for a rearrangement of the specimen, which would falsify the measured values. It can also display height change by servo measuring system.

After simply loosening the front frame reinforcement the specimen can be inserted into a flexible test base plate. This makes the testing device very effective and space-saving.

Software allows for a flexible parameter entry, the execution of different testing procedures, a graphical representation of measured values, test evaluation, and logging. Then the pre-set number of cycles is reached, the test is ended automatically.

(3) EDGE TEST

The machine increases mattress fatigue test function, it simulate human sitting on the edge of mattress, with 1000N force to test the fatigue of mattress for 5000 cyclic according to EN1725.

|

Durability Test Technical Specifications |

|

|

Hexagonal Wood Barrel (ASTM F 1566) |

109kg, length 915±75 mm |

|

Cylinder wood barrel (EN1957) |

140kg, length 1000mm |

|

Maximum size of mattress |

2200m×2000m×400mm |

|

Test speed |

0-20 r/min |

|

Control method |

PLC |

|

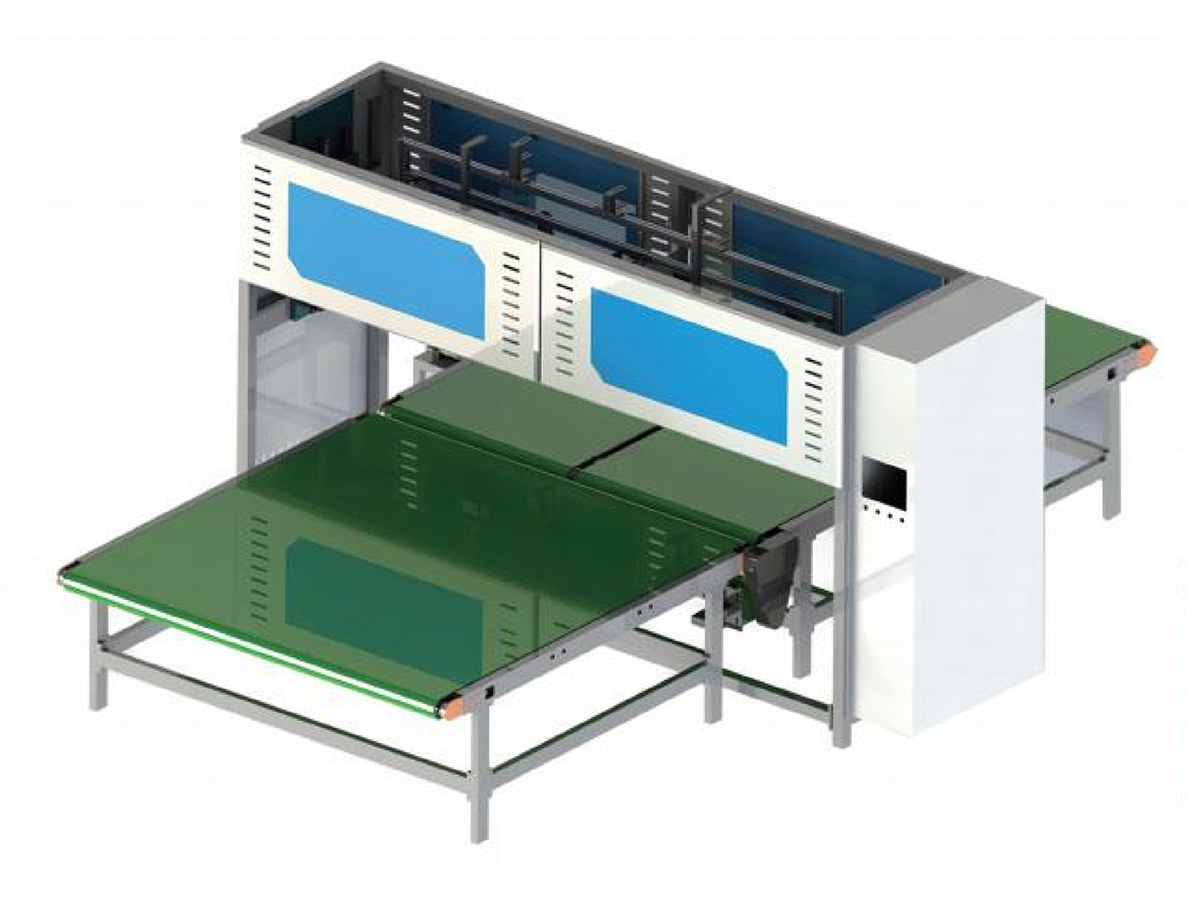

Dimension |

2900mm×2700mm×1800mm |

|

Power |

AC380V±10%, 50/60Hz, three phase |

|

According to different mattress to adjust the rolling stroke (adjust the limit switch position) |

|

|

Low coefficient of friction guide, ensure full drum weight on the mattress. |

|

|

The LCD Touch Screen display provides easy control and setting. |

|

|

EN hardness & height change test Technical Specifications |

|

|

Load block |

Diameter 355 mm, Spherical radius of curvature 800mm, Front edge radius of curvature 20mm |

|

Speed |

90mm/min |

|

Stroke |

350mm |

|

Driving method |

SMC brand electric cylinder |

|

Load cell |

200kg (Germany brand tecsis) |

|

Load plate position adjustment |

300mm |

|

Height change test |

|

|

Test method |

High-precision servo measuring system |

|

EDGE TEST Technical Specifications |

|

|

Test Force |

1000N |

|

Driving method |

Air cylinder |

|

Times |

5000 cycles |

|

Hold time |

3S |

Please make sure your contact information iscorrect. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.