- HOME

- MATTRESS MACHINE

- FOAM MACHINE

- PILLOW MACHINE

- SOFA MACHINE

- PROJECT SOLUTION

- NEWS

- COMPANY PROFILE

- CONTACT US

|

Available Wire Diameter |

Φ2.5 ~ Φ5.0mm |

|

Available Spring Pitch |

16-60mm (can be customized) |

|

Available Spring Height |

28-100mm |

|

Cutting Length at one time |

200-800mm |

Product Description

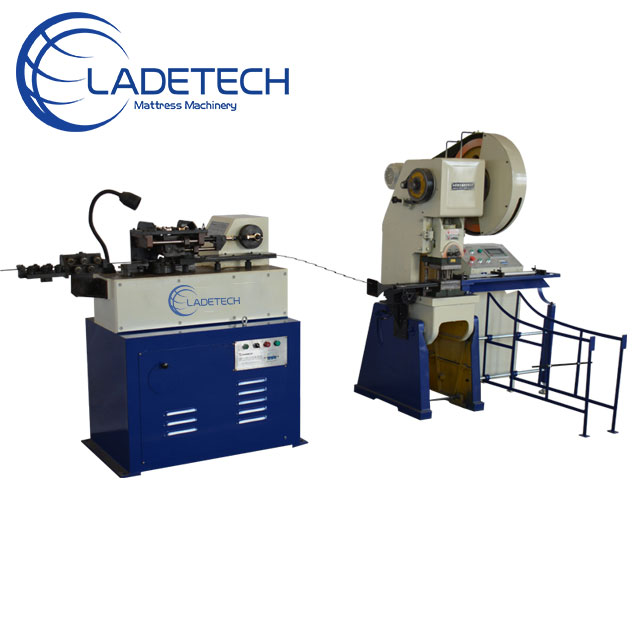

LDT-SFL Automatic zig zag sofa spring production line consists of two parts: forming machine and stamp cutting machine. It is an ideal equipment to produce special springs for sofas and car seat cushions. The utility model is equipped with servo motor controlled by the computer program, which accurately conveys the curved spring according to the set number of sections, and cuts the bending forming at the same time.

Technical Characteristics

1. Realize human-machine interface, fully automated.

2. Produce two kinds of springs -flat spring and arch spring.

3. When the steel wire is used up, it will automatically stop working.

4. High efficiency, extensive spring specification range.

5. Easy to operate and easy to maintain.

|

Technical Specification |

|

|

Available Wire Diameter |

Φ2.5 ~ Φ5.0mm |

|

Available Spring Pitch |

16-60mm (can be customized) |

|

Available Spring Height |

28-100mm |

|

Cutting Length at one time |

200-800mm |

|

Productivity |

280 peaks/min |

|

Total Power |

4 KW |

|

Weight |

1100 KG |

Please make sure your contact information iscorrect. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.